For any supply chain to run without hiccups, it’s not just about having the right systems, processes, or logistics networks in place.

The quality of the underlying data matters just as much, and often more than the technical platforms themselves. If the data is off, even slightly, everything else can fall apart, and that’s something many organizations tend to underestimate.

In practice, maintaining the accuracy of master data, covering things like materials, locations, and shipping details, is harder than it looks.

More often than not, organizations have processes for operations and tech that are well-oiled, but the data itself lags behind.

A miscategorized item, a supplier record not updated, or a storage location recorded incorrectly, any of these smallest things can also ripple across the supply chain.

Stock ends up in the wrong place, with delayed shipments, and halted production for hours, days or even months, as per some of our clients.

Think about a plant gearing up for a busy production season. Everyone, right from the warehousing team, to the production and maintenance teams, need to be coordinated.

Materials must arrive when expected, storage capacity has to be ready, and deliveries have to match the schedule.

The Material and Product Master tells you what to move, the Location Master says where, and the Transportation Master governs how.

Get even one of these wrong, and the results can be costly and frustrating.

So, while it’s easy to focus on fancy tech platforms, the truth is that the reliability of the supply chain depends on clean, accurate, and synchronized master data.

Organizations that recognize this, and treat data quality as a strategic priority rather than a checklist item, are the ones that can avoid disruptions, optimize inventory, and keep operations flowing smoothly.

What is Supply Chain Master Data?

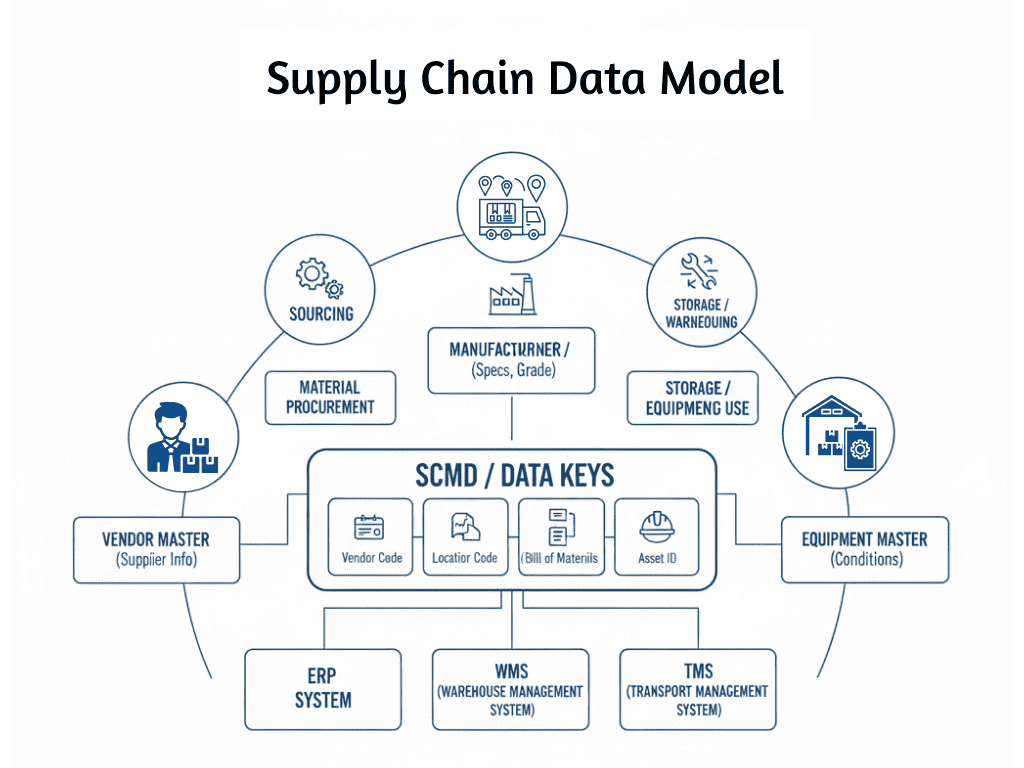

Supply Chain Master Data, or SCMD, refers to the core data domains, like materials, services, suppliers, customers, locations, or asset master, that supply chain teams rely on when performing various functions like procurement, production, delivery and storage or warehousing.

Unlike transactional data, that keeps changing frequently, SCMD remains relatively stable and acts as a constant foundation for planning and execution systems.

This data drives how processes interact across the systems such as ERP, Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and Manufacturing Execution Systems (MES).

Its inaccuracy or incompletence reflects the consequences that can appear in unexpected ways like delays, errors, or misrouted operations, causing huge revenue losses.

Briefly, SCMD defines the rules that keep supply chain operations running smoothly. It may not always be visible, but its accuracy and consistency are critical to day-to-day operations.

SCMD Domains and Interconnections

Supply Chain Master Data is not a single database; but it is a function that is impacted by how different data domains are managed.

It is a linked data model, distributed across systems yet interdependent through shared identifiers known as data keys, just like a material number, any part specifications, a vendor code, an equipment tag, or the service category codes.

Each domain represents a specific operational entity, but its usefulness lies in how it connects with others.

For instance, say in the case of an industrial valve being sourced, manufactured, stored, and shipped:

| Step | Data Domain | What It Defines / Provides | Impact if Incorrect |

|---|---|---|---|

| Sourcing | Vendor Master | Supplier details, lead times, contact info | Delays in procurement, wrong supplier selected |

| Material Procurement | Material Master | Material ID, size, specifications, grade | Wrong materials ordered, quality issues |

| Manufacturing / Production | Material Master | BOMs, part specifications | Incorrect parts produced, rework required |

| Storage / Warehousing | Location Master | Warehouse location, storage conditions, handling requirements | Items stored incorrectly, spoilage, safety issues |

| Handling / Equipment Use | Equipment Master | Tools and machinery required for safe handling | Damage to materials, safety risks |

| Transportation / Delivery | TMS (Transport Mgmt) | Shipment planning, routing, carrier selection | Delays, misrouted shipments, higher logistics costs |

| Overall Data Governance | SCMD / Data Keys | Shared identifiers (Material ID, Vendor Code, Location Code, Asset ID) | Disconnected data, errors propagate across the supply chain |

If any of this data is incorrect, the shipment can be delayed or misrouted.

Every one of these actions depends on a single, consistent reference model. If even one field, say the product’s weight, supplier code, or storage condition is incorrect, the chain breaks: the shipment might be delayed, incorrectly routed, or even non-compliant.

Below is a deep dive of how different data domains impact the supply chain functions

Materials Master

The Material Master is the beginning for any supply chain operation. Every movement, whether it involves raw materials from a supplier or finished goods delivered to a customer, begins with how the material itself is defined.

In manufacturing industries, where materials flow from production plants to warehouses, and from there to customer sites or service centres, the accuracy of these movements depends on the precision of material data that defines what is being moved, in what form, and under what handling conditions.

Each material record within the Supply Chain data carries standardized identifiers and attributes, specification codes, dimensions, unit of measure, Bill of Materials (BOM) references, and standard cost, like

| Attribute | Example Value |

|---|---|

| Material ID | VAL-002 |

| Specification Code | SS-2IN-300 |

| Dimensions | 2″ diameter × 6″ length |

| Unit of Measure | Each |

| BOM References | Assembly BOM #BOM-101 |

| Standard Cost | $45.00 |

These attributes are not static; they guide the rules by which enterprise systems like ERP, WMS, and TMS execute their respective functions.

A single material code links sourcing, manufacturing, quality, and logistics operations, serving as the common denominator across the entire digital supply chain.

Materials are of different varieties, including direct, indirect. In direct material flows, such as those in automotive, electronics, or discrete manufacturing, material master data drives procurement and production synchronization.

A single spare part may be sourced from multiple suppliers or could be produced in different plants. Its master data ensures that these transactions use consistent technical descriptions, lead times, and cost structures.

If the data for even one supplier or component is misaligned, production planning and MRP outputs can become inaccurate, leading to shortages or overproduction.

For example, consider for a hydraulic pump,

| Supply Chain Function | Data/Action Linked to Material ID | Impact/Outcome |

|---|---|---|

| Procurement | Orders placed with Supplier A or Supplier B using Material ID | Ensures correct specification, price, and lead time |

| Manufacturing / Production | Referenced in BOMs at Plant X and Plant Y | Consistent assembly and product quality |

| Quality Control | Checks technical description, material type, and compliance | Ensures product meets required standards |

| Logistics / Warehousing | Tracks storage location, shipping, and inventory using Material ID | Accurate inventory, proper handling, and timely delivery |

In process industries such as chemicals, energy, or oil and gas, material master data governs the complex networks of intermediate and processed materials.

These materials often change state, like crude to refined, for example, crude oil being processed into gasoline, or from bulk to blended, such as blending chemicals to produce a cleaning solution.

They require tracking through batch numbers, grades, and hazard classifications to maintain quality, safety, and environmental compliance.

| Batch Number | Material State | Grade / Purity | Hazard Classification | Environmental Notes |

|---|---|---|---|---|

| BATCH-20251128-01 | Crude Oil | N/A | Flammable Liquid, Class 3 | Stored in designated tanks with spill containment |

| BATCH-20251128-02 | Refined Gasoline | Standard Grade 95 | Flammable Liquid, Class 3 | Monitored VOC emissions during refining |

| BATCH-20251128-03 | Bulk Chemical Blend | Technical Grade | Corrosive, Class 8 | Blending done in closed systems; waste neutralized |

| BATCH-20251128-04 | Packaged Solution | Lab Grade | Flammable / Irritant | Packaged in compliant containers; labeling per regulations |

Any inconsistency in material attributes such as density, purity, or flash point can have cascading effects on product quality, regulatory reporting, and safety compliance.

SCMD ensures that these dynamic movements remain governed by consistent, validated records across production and logistics systems.

Indirect materials and MRO spares represent another critical aspect. They may not enter the final product but sustain the operational capability of production assets. Their data connects maintenance schedules, equipment IDs, and supplier records.

For example, if a turbine requires a specific gasket or seal, the accuracy of that material code determines whether maintenance work can proceed as planned.

Any mismatch between material master and asset master data can delay maintenance, causing downtime and revenue loss.

Research into maintenance data quality in process industries Using data mining technology to explore causes of inaccurate reliability data and suggestions for maintenance management found that poor-quality maintenance/asset data undermines reliability calculations, inspection schedules, and integrity‑management outcomes.

Product Master

Product Master Data defines how an item is represented commercially and operationally in the supply chain.

While the Material Master describes the physical characteristics of what is being handled, the Product Master determines how it is configured, priced, packaged, and delivered to the market.

Product master attributes includes SKU identifiers, GTIN or barcode values, brand hierarchies, packaging levels, shelf-life requirements, and phase-in or phase-out status.

These attributes directly influence channel distribution, inventory segmentation, and replenishment strategies.

In supply chain planning, product hierarchies determine how forecasting is performed at category, family, or SKU level.

If product relationships are not structured correctly, demand aggregation becomes distorted, resulting in inaccurate forecasts and poor stock allocation.

During warehousing and logistics execution, product packaging dimensions drive cartonization rules, pallet stacking limitations, and load building in WMS and TMS.

| Supply Chain Area | Attribute / Structure Used | Example Scenario | Impact / Outcome |

|---|---|---|---|

| Channel Distribution | Product Type, Market Segment | A premium variant and an economy variant of the same item | Premium SKU routed to retail outlets; economy SKU routed to wholesale distributors |

| Inventory Segmentation | ABC classification, Storage Temperature, Hazard Class | A chemical product available in high-purity and industrial-grade | High-purity stored in climate-controlled racks; industrial-grade stored in bulk zones |

| Replenishment Strategy | Lead Time, Demand Variability, Safety Stock Parameters | Fast-moving spare part with high order frequency | System triggers frequent automated replenishment cycles |

| Demand Forecasting (Planning) | Product Hierarchy: Category → Family → SKU | Beverages grouped into “Energy Drinks” → “500 ml” → individual SKUs | Forecasting at family level smooths variability and improves planning accuracy |

| Warehousing Operations | Packaging Dimensions, Weight, Handling Units | A boxed item (10×8×6 in) vs. a bulk drum | Small box assigned to pick shelves; drum assigned to floor storage |

| Logistics Execution | Palletization Rules, Stackability, Transport Class | Cartons that cannot be stacked due to fragility | TMS |

The “Product Master Data Quality” study found that poor product data significantly degrades logistics performance, causing disruptions in distribution and shipping processes.

Misconfigured product data may lead to inefficient space utilization, costlier transportation, or damage in handling due to incorrect stacking assumptions.

In regulated sectors such as pharma and food, product data also acts as the anchor for compliance requirements.

Serialization, batch traceability, allergen labeling, and expiry controls all depend on accurate product-level attributes to ensure consumer safety and regulatory adherence.

Product master data therefore acts as the bridge between operational capability and commercial promise. It ensures that what is produced in the factory is exactly what is sold in the market, via channels that support the correct format, volume, and safety parameters.

Customer Master

Customer Master Data defines where, how, and to whom the products have to be delivered.

It presents the demand side of the supply chain and governs complete accuracy, delivery performance, and customer experience.

Core customer attributes include

| Attribute | Example Value | Why It Matters |

|---|---|---|

| Delivery Address | 1200 Motorway Dr, Plant 4, Dock C | Ensures the truck arrives at the correct production facility. |

| Location ID | AUTO-PLT-004 | Unique ID for planning, routing, and system mapping. |

| Unloading Constraints | Forklift unloading only; no manual handling | Ensures correct equipment is sent with the truck. |

| Dock Type | Standard 48” dock | Determines trailer type and height compatibility. |

| Order Cycle Policy | Weekly deliveries every Tuesday | Guides planning and replenishment cycles. |

| Credit Terms | Net 60 | Impacts invoicing and financial processing. |

| Product Eligibility Rules | Only approved brake components allowed | Prevents shipment of unapproved or incompatible parts. |

These records ensure logistics processes follow predefined service expectations.

In B2B supply chains, customer masters often represent large enterprises, distributors, or industrial buyers.

Delivery windows, pallet configuration rules, and documentation standards (such as ASNs or CoA certificates) are captured within the customer master. Any error in these parameters may result in rejected loads, penalties, and costly re-deliveries.

For example, a retail distribution center may require pallets stacked to exactly 72 inches and ASNs transmitted at least 2 hours before arrival, failure to comply can lead to penalties ranging from $150 to $1,000 per load depending on retailer policies.

Any error in these parameters may result in rejected loads, re-delivery charges, or reduced supplier performance scores.

According to Supply & Demand Chain Executive,

In retail / last-mile delivery contexts, poor or incomplete customer address data increases the risk of failed deliveries. As one industry article notes, these address-data problems are a “common cause” of last-mile delivery failures, leading to returned packages, delays and customer dissatisfaction.

In B2C and omni-channel environments, customer data expands further to include last-mile delivery instructions, regional labeling preferences, and return policies.

High volumes of unique end-customer records require advanced data governance to avoid duplication and routing inefficiencies.

Customer master also influences demand planning and order prioritization.

According to a research report published by International Journal for Multidisciplinary Research (IJFMR)

Data-quality issues in supply chains are repeatedly linked to “inventory mismatches, incorrect shipments, and billing errors,” which in turn degrade supply-chain efficiency and customer satisfaction.

Strategic customers may have service-level commitments, like guaranteed stock allocation during shortages or differentiated lead times. These rules automate fulfillment decisions across ERP, OMS, and WMS systems.

When connected properly with product and location masters, customer master data forms the execution blueprint for order fulfillment.

Accurate records ensure that what is planned is deliverable, what is shipped arrives correctly, and customer relationships remain profitable.

Vendor Master

Vendor Master Data defines the external entities that supply materials, provide logistics services, or support maintenance and operations.

It includes key attributes such as legal name, payment terms, supply categories, lead times, performance ratings, and compliance certifications.

In procurement, clean vendor data ensures seamless creation of purchase orders, accurate supplier selection, and contract adherence. A single incorrect vendor code can delay sourcing cycles, block invoice processing, or trigger compliance risks.

For supply chain planning, supplier-linked attributes such as delivery lead time, minimum order quantities, and sourcing locations directly influence MRP outputs and replenishment decisions.

For example,

| Vendor | Category | Lead Time | MOQ | Certifications | Performance Rating |

|---|---|---|---|---|---|

| Precision Gear Components Inc. | Supplier of transmission gears for automotive OEMs | 15 days | 1,000 units | ISO 9001, IATF 16949 | 95% OTIF |

How it works in practice:

→ Procurement: Clean vendor master ensures purchase orders select the correct supplier.

If the wrong vendor code is used, invoices fail 3-way match, delaying payment by up to 10–15 days (common benchmark in AP error research).

→ Planning / MRP: The 15-day lead time feeds MRP.

If lead time is mistakenly maintained as 7 days, planning underestimates replenishment needs → shortage risk → line stoppage.

→ MRO & Quality: Only vendors with IATF 16949 certification are approved to supply critical gears.

Incorrect certification info could result in unapproved suppliers slipping into the process → quality and regulatory risks.

→ Inbound Logistics: Vendor geolocation allows TMS to optimize routing.

Incorrect coordinates can increase inbound transportation cost by 5–12% due to misrouted carrier assignments (industry estimate based on TMS routing inefficiencies).

Inaccurate values can distort demand forecasts and cause either shortages or excess stock.

In MRO environments, linking Vendor Master Data with spare parts and equipment records ensures that critical components are always sourced from approved suppliers who meet quality and safety standards.

Poor linkage may result in the procurement of incompatible or low-quality parts, potentially leading to equipment failure.

Research conducted by The Hackett Group revealed the following insight

Global procurement governance studies highlight that duplicate or incorrect vendor records cause 2–5% maverick spend or leakage, due to misrouted orders and inconsistent pricing.

Vendor Master Data also supports logistics efficiency.

For example, integrating geolocation and freight terms allows transportation systems to automate routing logic and optimize inbound delivery schedules.

Ultimately, the Vendor Master is a strategic enabler of supply chain resilience.

When synchronized with Material, Location, and Purchasing Masters, it strengthens supplier collaboration, improves compliance, and enhances operational continuity.

Location Master

Every material movement in the supply chain begins and ends at a physical node. These nodes, such as plants, vendor sites, cross-docks, distribution centres, and customer delivery points, are governed by Location Master Data.

This dataset defines where operations occur, how goods flow between facilities, and which regulatory requirements apply to each jurisdiction.

Attributes such as geospatial coordinates, access restrictions, security level, and operating hours directly influence operational feasibility and transportation routing.

Even minor inaccuracies, like an incorrect pin code or customs region, can disrupt routing, documentation, and delivery performance, especially in cross-border operations.

In e‑commerce / last‑mile delivery, a recent industry analysis by Smartroutes reports that

About 45% of failed deliveries are due to address errors (wrong or incomplete address data), illustrating the real cost of bad location data.

The Location Master ensures that every transaction references a validated and reachable destination, preventing system errors and routing failures.

Warehouse Master

Warehouse Master Data builds on the location dataset by describing the internal structure and storage logic of a facility. It governs how and where materials move once inside the warehouse perimeter.

Core attributes include storage zones, temperature classifications, material handling equipment compatibility, bin dimensions, and picking sequence rules.

These data points feed Warehouse Management Systems (WMS), enabling accurate slotting, optimization of vertical space, and avoidance of incompatible storage placements.

For example, in a pharmaceutical cold chain warehouse,

| Attribute | Example Value | Impact on Operations |

|---|---|---|

| Storage Zone | Cold Zone A | Ensures temperature-sensitive drugs are stored at the correct zone. |

| Temperature Classification | 2–8°C | Maintains product efficacy and regulatory compliance. |

| Material Handling Equipment Compatibility | Forklift with temperature-controlled compartment | Prevents damage or exposure during movement. |

| Bin Dimensions | 1.2m × 0.8m × 0.6m | Supports proper slotting and optimal space utilization. |

| Picking Sequence Rules | FEFO (First Expired, First Out) | Ensures older stock is shipped first, preventing expiry. |

| Special Compliance Requirement | Cold chain traceability logging | Enables audit-ready records and regulatory compliance. |

If this linkage fails, inventory could be stored incorrectly, resulting in spoilage or safety violations.

Warehouse master data ensures that the physical flow of goods aligns with digital execution, protecting both operational efficiency and product integrity.

Transportation Master

Transportation Master Data defines how goods move between nodes. It governs the relationship between carriers, lanes, service levels, shipment methods, and freight constraints.

Key attributes include approved carrier lists, route lane IDs, transit times, vehicle capacity limits, freight class, Incoterms, and delivery frequency rules.

These parameters are essential for Transportation Management Systems (TMS) to generate feasible, cost-effective routing plans.

This dataset enforces compliance by matching freight requirements to certified carriers.

For example, hazardous materials can only be assigned to carriers with proper certifications, while oversized loads must match vehicles with appropriate axle and height allowances.

Incorrect transportation master data causes downstream failures such as rejected loads, unexpected detention fees, and inflated freight costs due to poor space utilization.

An industry discussion by Intelligent Audit notes that,

Incorrect or incomplete carrier/route/shipment data frequently leads to routing issues and misdeliveries, especially when cargo attributes or destination constraints are wrong.

Accurate transportation data ensures predictable and resilient logistics execution across global networks.

Service Master

While physical goods dominate traditional supply chain discussions, Service Master Data plays an equally critical role in modern, service-intensive supply chains.

It defines all recurring and non-recurring service activities, right from logistics operations such as transportation and customs clearance to maintenance, inspection, third-party warehousing, and other non-material processes.

For logistics and 3PL providers, service master data governs how services are scheduled, priced, and executed.

For instance, a 3PL might maintain over 500 standardized service codes covering activities such as inbound handling, cross-docking, palletization, quality checks, and value-added services.

These codes ensure every service is triggered and billed consistently across customers and locations.

A well-maintained service data ensures that activities align with material flows;

For example, a maintenance work order may require both spare parts (from the Material Master) and a third-party technician (from the Service Master).

Proper integration allows procurement, scheduling, and financial postings to occur seamlessly.

From a governance perspective, service master data ensures contractual transparency and operational traceability.

It standardizes how services are identified and tracked, allowing procurement and finance teams to evaluate vendor performance, manage budgets, and ensure compliance with service-level agreements.

In modern supply chains, where physical flows are increasingly supported by service-based activities, such as outsourcing logistics, maintenance, and aftersales, this domain provides the operational backbone for service-oriented planning and billing processes.

Asset Master

The Asset Master define the technical and operational identity of every physical resource that supports supply chain execution.

This includes production machinery, handling equipment, transport vehicles, and critical infrastructure such as conveyors, cranes, and packaging lines.

In manufacturing, this dataset links directly to production planning and capacity management. Each equipment record holds attributes such as rated throughput, setup time, maintenance frequency, and associated work centres.

These details enable Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) modules to determine feasible production schedules.

If capacity data is inaccurate, systems may overcommit production runs or trigger unplanned downtime when machines reach operational limits.

According to a Deloitte report,

Across industry, unplanned downtime costs manufacturers an estimated USD 50 billion annually, with nearly 42% attributed to equipment failure, a clear indicator of the importance of reliable asset data

For logistics operations, equipment data extends beyond factory floors. Fleet vehicles, trailers, forklifts, and even automated guided vehicles (AGVs) are defined in the Asset Master, each carrying operational parameters such as payload limits, fuel type, and maintenance intervals.

This information is essential for Transportation Management Systems (TMS) and Warehouse Management Systems (WMS) to plan asset utilization efficiently.

Asset data also forms the foundation for predictive maintenance and condition-based monitoring.

By linking equipment performance data from IoT sensors with master data attributes, AI-driven systems can predict potential failures and schedule maintenance before disruptions occur.

This integration ensures that supply chain operations remain uninterrupted and maintenance windows are planned around production and logistics commitments.

A strong connection also exists between the Asset Master and Material Master. Each asset consumes spare parts and consumables that are defined as materials, creating a closed feedback loop between maintenance and supply chain replenishment.

If the equipment ID in a work order management system does not correctly link to the corresponding spare part codes, procurement and inventory systems may fail to issue replacements on time.

Asset master data acts as the reliability layer of the supply chain. It governs not only the physical capacity of operations but also the resilience and responsiveness of the network.

Accurate, well-governed asset data ensures that plants, fleets, and warehouses operate at designed efficiency, reducing both downtime and cost variability across the end-to-end supply chain.

When these linkages are missing or misaligned, the effects ripple across systems. An incorrect location key may send materials to the wrong site, while a mismatched vendor key could delay procurement cycles.

Hence, data key governance, ensuring every entity is uniquely identified and consistently linked, is a foundational capability of SCMD maturity.

Effectively managed, these interconnections form the digital twin of the supply chain, where each product, asset, and transaction can be traced across its lifecycle.

It transforms master data from a static reference set into a dynamic operational backbone that supports different functions like planning, execution, and continuous improvement.

Functions and Disciplines Impacted by Master Data

Supply Chain Master Data acts as the structural foundation on which all supply chain transactions are executed.

Each business process, be it procurement, production planning, logistics, or inventory management, they depend on the accuracy and connectivity of master records to function effectively.

When data is synchronized, these processes run predictably and efficiently; when it is inconsistent, the effects cascade across systems, leading to delays, excess costs, and operational risk.

Procurement operations rely heavily on data accuracy across Material Master, Vendor Master, and Service Master datasets. Each purchase order draws directly from the material’s unique identifier, its specifications, and sourcing details stored in the master data.

The Vendor Master provides supplier contact information, payment terms, lead times, and performance history, ensuring the correct supplier is engaged under valid contract terms.

Inconsistent supplier codes or obsolete material IDs can result in duplicate orders, pricing discrepancies, or even procurement of non-approved materials.

Conversely, when procurement master data is harmonized with the Source List and Approved Vendor List, purchase requisitions can be automatically routed to preferred suppliers, improving compliance and reducing cycle times.

For service-based supply chains, the Service Master ensures that logistics partners, maintenance vendors, and transport providers are accurately catalogued, allowing seamless purchase order generation for both tangible goods and operational services.

Production planning relies on the seamless integration of multiple master data domains across Material, Bill of Materials (BOM), Routing, Work Centre, and Equipment Masters.

Together, these form what many organizations refer to as Manufacturing Master Data, which defines how products should be produced and which resources are required at each stage.

The Material Master defines what is to be manufactured, while the BOM specifies which components will be consumed in the process.

Routing and Work Centre masters define how and where production should take place, including machine assignments, labor skills, cycle times, and operational sequences.

Equipment maintenance further contribute by capturing asset capabilities, maintenance status, and capacity constraints.

When any of this data is inaccurate or outdated, the impact is immediate.

A missing component in a BOM, an incorrect operation time in routing, or an obsolete work centre can trigger flawed MRP outputs, inefficient production schedules, and avoidable bottlenecks.

Integrated SCMD ensures that planning systems generate feasible production orders, accurately calculate material and capacity requirements, and align demand with shop floor execution.

In process industries like chemicals, pharmaceuticals, energy, or oil and gas, manufacturing master data governs recipes, batch formulations, unit of measure conversions, and regulatory parameters.

Attributes such as grade, purity, viscosity, flash point, or reaction constraints must be consistently defined.

Even a minor data discrepancy can cause batch failures, compliance issues, or costly rework.

In essence, manufacturing master data connects design intent with operational execution.

It ensures that production planning is not just automated but also realistic, resource-aware, and fully aligned with physical manufacturing capabilities.

Logistics is where the Location, Warehouse, Customer, and Transport Master Data domains converge.

Each shipment, route, and delivery plan depends on precise location data and correct mapping between customer destinations and warehouse origins.

The Customer Master defines not only delivery addresses but also service-level agreements (SLAs), packaging preferences, and billing requirements.

When this data is synchronized with carrier and vehicle records in the Transport Master, transportation management systems (TMS) can automatically assign optimal routes and modes.

For organizations operating in both B2B and B2C environments, customer master accuracy ensures that shipments align with business-specific rules, bulk orders for industrial customers, or parcel-level fulfilment for end consumers.

Poorly maintained location or transport data can lead to delivery errors, route inefficiencies, or compliance failures in regulated industries.

High-quality SCMD minimizes such risks by giving every system, from ERP to WMS to TMS, a single source of verified truth.

Inventory management becomes a predictive and optimized function when guided by accurate and well-structured master data.

Inventory data forms the operational core of supply chain responsiveness. While stock levels themselves are transactional, the governing parameters fall under Supply Chain Master Data (SCMD).

These include Safety Stock Levels, Reorder Points, Minimum and Maximum Order Quantities (MOQs), lead times, and spare parts classification rules such as ABC or XYZ segmentation.

Each of these parameters influences planning engines like MRP and DRP. For example, safety stock acts as a buffer against demand fluctuations, while lead times trigger timely replenishment.

Any inaccuracies can result in stockouts, inflated inventories, or emergency procurement, directly impacting operational performance.

The inventory management rules within MRO operations are especially dependent on master data accuracy. Here, spare parts are low-usage but high-impact items.

Understanding and evaluating the criticality of spare parts ensures that stocking policies align with operational risk rather than purely historical consumption.

Spare parts management rules, covering criticality ratings, reorder policies, and obsolescence markers, are tied to Equipment Masters and Maintenance Plans.

When these are synchronized, maintenance execution is never delayed due to missing parts, reducing downtime and cost exposure.

With advanced planning and AI-enabled insights, organizations can proactively adjust safety stocks and reorder points based on usage trends and asset health data.

This transforms spare part replenishment from a manual, reactive exercise into a predictive capability that protects production continuity.

Overall, effective SCMD-driven inventory governance ensures that goods and spares are available in the right place, at the right time, and at the right cost.

It strengthens supply assurance, reduces working capital pressure, and reinforces operational reliability across the entire supply chain.

Key Characteristics of Supply Chain Master Data

- Operational data: Day-to-day details like inventory and production schedules

- Transactional data: Records of orders, shipments, and payments

- Performance data: Metrics tracking supplier reliability and quality

- Predictive data: Forward-looking analytics to anticipate changes

But here’s the challenge: Without proper management, this data exists in silos, creating inconsistencies that lead to inefficiencies, missed opportunities, and increased vulnerability to disruptions.

Implementing MDM in Your Supply Chain

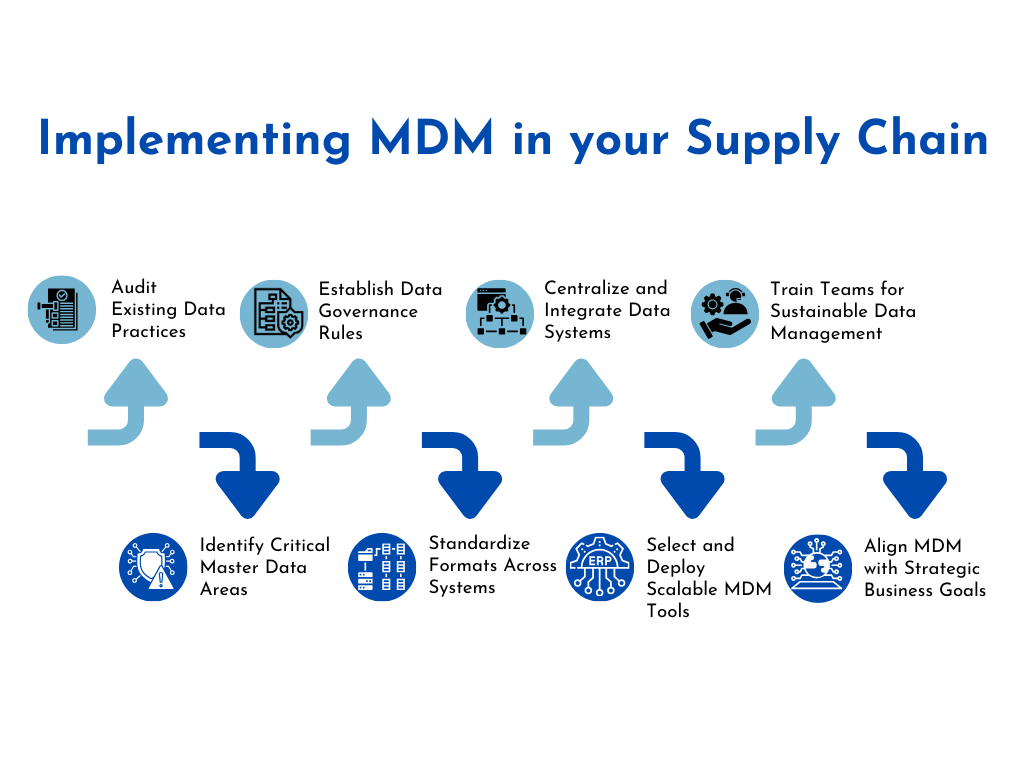

Assess Current Practices – Identify inefficiencies in supplier data, inventory records, and logistics tracking. Address issues like duplicate entries, inconsistent formats, and missing details.

Define Key Master Data Domains – Focus on product, supplier, customer, location, and inventory data to streamline procurement, production, and distribution.

Develop Governance Frameworks – Establish data ownership, approval workflows, and validation rules to maintain accuracy, compliance, and consistency.

Standardize Data Formats – Ensure uniform naming conventions, measurement units, and data fields across ERP, WMS, and procurement systems.

Bridge Data Gaps – Validate missing or outdated information using internal cross-references and external sources like supplier databases and regulatory records.

Consolidate Disparate Data – Migrate legacy systems into a centralized MDM platform, enabling real-time data synchronization and eliminating silos.

Select Scalable MDM Solutions – Choose software with integration capabilities, automation features, and AI-driven insights for predictive supply chain management.

Train Your Team – Conduct role-specific training for procurement, logistics, and IT teams to ensure proper usage and governance of MDM tools.

Monitor and Maintain Data Quality – Implement automated audits and periodic manual reviews to detect errors, redundancies, and outdated records.

Align MDM with Business Goals – Integrate MDM with analytics, sustainability tracking, and market expansion plans to drive efficiency and competitiveness.

Conclusion

In today’s unpredictable operating landscape, supply chain effectiveness is not a competitive advantage; it is a fundamental requirement for continuity and growth.

Master Data Management elevates the supply chain from a fragmented risk area into a governed business asset, enabling organizations to execute with speed, accuracy, and resilience.

With a unified and trusted data foundation, enterprises can sense disruptions earlier, respond with precision, and align decisions across procurement, planning, warehousing, logistics, and finance.

The real question is no longer “Can we invest in MDM?” but “Can we afford the operational risk of not having it?”

As global networks become more interconnected and exposed to disruption, the companies that institutionalize strong MDM practices will be the ones that maintain business continuity, unlock efficiency gains, and build supply chains capable of thriving in the future of commerce.