The MESC (Material and Equipment Standards and Code) is a hierarchical classification system designed to provide a consistent, standardized framework for identifying and procuring materials, spare parts, and equipment used in industrial operations.

Developed by Shell in 1932 and since licensed globally, MESC enables organizations to assign a unique, descriptive 10-digit code to any material-ensuring that a valve specified in a refinery in Oman is the identical part received in a facility in Rotterdam, regardless of supplier or manufacturer.

Key Characteristics:

Attribute | Details |

Origin | Created by Shell (1932); later licensed to global enterprises across oil, gas, chemical, power sectors |

Code Format | 10-digit hierarchical structure (XX.XX.XX.XXX.X) |

Scope | Covers ~80+ material categories; supports 110,000+ standardized items |

Coverage | Materials, equipment, spare parts, maintenance consumables, MRO supplies |

Languages | English-based primary; translations available for regional adaptation |

Flexibility | Central coding (global) + local coding (regional customization) |

Integration | Cross-references to ISO, API, ASTM, IEC international standards |

Unlike supplier-specific catalogs or internal nomenclature-which fragment data and obscure duplicates-MESC creates a universal taxonomy that bridges procurement systems, inventory management, maintenance operations, and supply chain governance.

What is MESC SPE?

MESC SPE stands for “MESC Standard Purchase Equipment Specifications” – the engineering-grade technical documents that define exact requirements for materials coded in the MESC system.

What Are MESC SPEs?

Each MESC code links to one or more SPE documents that specify:

Category | MESC SPE Examples | Covers |

Valves | SPE 77/300, 77/200, 77/302 | Ball, gate, globe valves |

Piping | SPE 74/019, 76/100 | Pipes, flanges, fittings |

Instruments | SPE 60/100 series | Pressure gauges, transmitters |

Mechanical | SPE 27/100 series | Pumps, compressors |

SPE Structure & Purpose

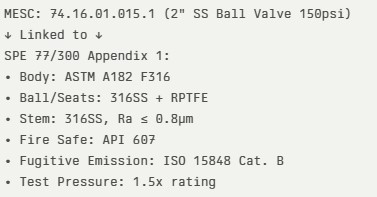

MESC Code 74.16.01.015.1 → Links to → SPE 77/300 (Ball Valves)

Each SPE contains:

Materials of construction (e.g., ASTM A351 CF8M for SS valves)

Design pressures/temperatures

Testing requirements (API 598, EN 13555, fugitive emissions)

Dimensional standards (face-to-face, flange ratings)

Coatings & surface finishes

Marking & documentation

Real Example: Ball Valve SPE 77/300

Bottom Line: MESC numbers identify what to buy. SPEs define exactly how it gets built. Together, they create the most precise industrial procurement system ever developed.

Industries That Rely on MESC

In asset-heavy industries where precision, safety, and cost control are non-negotiable, MESC is foundational:

Oil & Gas (Upstream, Midstream, Downstream)

- Exploration & Drilling: Drilling tools, downhole equipment, wellhead components

- Refinery Operations: Pumps, valves, heat exchangers, instrumentation, maintenance spares

- Pipeline Operations: Piping systems, compressors, safety equipment, cathodic protection materials

- Offshore Facilities: Subsea equipment, topside infrastructure, emergency systems

Chemical Processing & Petrochemicals

- Reactors and distillation equipment

- Heat transfer equipment

- Process safety instrumentation

- Corrosion-resistant materials

Power Generation

- Turbine components

- Steam generation equipment

- Electrical systems

- Control and instrumentation

Heavy Manufacturing

- Industrial machinery

- Precision mechanical equipment

- Rotating equipment spares

- Structural materials

Who in the Organization Needs MESC?

MESC impacts multiple functions across industrial organizations:

- Role: Source materials using standardized codes; reduce supplier fragmentation; negotiate volume discounts

- Need: MESC codes enable consolidated sourcing, standardized specifications, and price negotiations across suppliers

- Benefit: 10–20% procurement cost reduction through consolidated volumes; faster RFQ turnaround

- Role: Specify equipment and materials; ensure technical compliance; integrate new equipment into operations

- Need: Precise material specifications aligned to operational requirements; cross-references to standards

- Benefit: Reduced specification errors; faster equipment selection; clearer communication with vendors

- Role: Identify correct parts for repairs; manage spare inventory; execute maintenance schedules

- Need: Unambiguous material identification; quick location of specifications; alignment with critical spares

- Benefit: Reduced downtime from incorrect parts; faster diagnosis; improved maintenance planning

- Role: Analyze procurement spend; track capital and operational costs; budget forecasting

- Need: Structured spend categories; accurate cost tracking; visibility into duplicate spend

- Benefit: 8–15% cost savings from duplicate elimination and spend consolidation; better budget forecasting

- Role: Manage stock levels; forecast demand; optimize inventory across sites; manage warehouses

- Need: Standardized item definitions; visibility into duplicates; accurate consumption forecasting

- Benefit: 15–20% inventory reduction; improved stock visibility; fewer stockouts and overstocking

- Role: Maintain master data; integrate procurement, inventory, and maintenance systems; data governance

- Need: Standardized data structures; clear material definitions; rules for code assignment

- Benefit: Cleaner master data; reduced system conflicts; improved data integration across platforms

What is MESC Number and Code Structure

An MESC number is a 10-digit hierarchical code that uniquely identifies any material, equipment, or spare part to an exact engineering specification -independent of manufacturer, supplier, or geography.

For Example:

68.68.61.301.1 = One specific telecommunication cable worldwide

Position | Digits | Level | Purpose | Example |

1-2 | 68 | Main Group | Broad family | Electrical equipment |

3-4 | 68 | Sub-group | Functional type | Cables & wiring |

5-6 | 61 | Sub-sub-group | Technical class | Polythene telecom cables |

7-9 | 301 | Buying Description | Exact variant | 110V, lead sheath, armored |

10 | 1 | Indicator | Scope/status | Central standard (.1) vs Local (.9) |

MESC organizes all materials using a rigid hierarchical structure. Each 10-digit code breaks down into five functional segments, progressively narrowing from broad classification to precise specification.

Segment 1 – Main Group (First 2 digits): Identification

The first two digits represent the broadest classification level, defining the primary material or equipment family. These Main Groups divide all materials into about 80+ high-level categories:

Main Group Code | Category | Examples |

27–31 | Mechanical Equipment | Pumps, compressors, turbines, heat exchangers |

50–57 | Structural Materials | Bolts, fasteners, welding materials, structural steel |

60–65 | Instrumentation | Pressure, temperature, flow measurement devices |

65–69 | Electrical Equipment | Cables, switchgear, motors, transformers |

74–85 | Piping & Valves | Pipes, fittings, flanges, valves (by service conditions) |

90–95 | Protective Materials | Coatings, paints, corrosion inhibitors, sealants |

Segment 2 – Sub-group (Second 2 digits): Categorization

The second pair of digits introduces subdivisions within each Main Group based on function or equipment type. This helps narrow the classification by purpose or use.

Example:

- Main Group 74 = Valves & Fittings

- Sub-group 74.10 = Gate Valves

- Sub-group 74.16 = Ball Valves

- Sub-group 74.20 = Check Valves

This structure allows procurement teams to quickly locate families of similar items while maintaining granular distinction.

Segment 3 – Sub-sub-group (Third 2 digits): Classification

The third pair of digits offers a deeper layer of categorization before reaching individual item identification. It focuses on exact technical features such as material composition, pressure rating, or configuration.

Example:

- Sub-group 74.16 = Ball Valves

- Sub-sub-group 74.1600 = Carbon Steel Ball Valves, 150 PSI

- Sub-sub-group 74.1601 = Stainless Steel Ball Valves, 150 PSI

- Sub-sub-group 74.1602 = Carbon Steel Ball Valves, 300 PSI

Segment 4 – Buying Description (Next 3 digits): Unique Item Specification

The fourth segment comprises three digits that identify a specific item variant within the classified category. This is where the actual product differentiation occurs-the buying description encodes the precise specification details.

Example:

- Code 74.1601.001 might specify a 1-inch stainless steel ball valve, full-bore, flanged ends, 150 PSI, ductile iron handles

- Code 74.1601.002 might specify the same valve in 1.5-inch size

- Code 74.1601.003 might specify a 2-inch variant

Segment 5 – Code Type Indicator (Last 1 digit): Scope Designation

The final digit distinguishes between global (central) and local coding standards:

Code Type | Digit | Meaning | Application |

Central Coded | 1 | Globally standardized, universally recognized | Used across multiple facilities and organizations; subject to rigorous technical review |

Local Coded | 9 | Regionally customized or organization-specific | Accommodates local supplier availability, regional compliance, or project-specific requirements |

The Strategic Distinction:

A telecommunication cable coded 68.68.61.301.1 represents a centrally-standardized specification recognized globally.

The identical cable with local color standards or regional modifications would be coded 68.68.61.301.9, signaling that while the core specification matches, local variations apply.

The MESC Framework: Three Integrated Components

Effective MESC implementation rests on three interconnected pillars:

- Classification Structure

The semantic framework enabling users to locate specifications using natural language concepts:

- Nouns (e.g., “valve,” “pump,” “cable”)

- Modifiers (e.g., “stainless steel,” “pressure-rated,” “high-temperature”)

- Synonyms (e.g., “coupling” vs. “connector,” “centrifugal” vs. “end-suction”)

This hybrid approach bridges human-readable descriptions and machine-readable codes, making the system accessible to both technical specialists and procurement professionals.

- Coding Schedule

The formal framework governing code assignment, including:

- Hierarchical grouping rules

- Assignment conventions for central vs. local codes

- Spare parts coding methodologies

- Cross-references to international standards

The Coding Schedule ensures consistency: a valve coded in a Shell facility in Oman follows identical logic to one specified in a BP plant in Rotterdam.

- MESC Catalogue

An extensive repository containing ~110,000 standardized material items, each including:

- Detailed buying descriptions

- Technical specifications (dimensions, materials, performance)

- Regulatory cross-references (ISO, API, ASTM, IEC)

- Supplier alignment data

- Quality assurance specifications

MESC Indicators

The last digit of the MESC number is known as the indicator and communicates how the item is governed within the MESC system.

Typical meanings include:

1 – Central (standard) item

Used for centrally approved catalogue items that are part of the official Shell/MESC standard and may be used across all locations.9 – Local item

Used where local modifications are necessary (e.g., national color codes, local certification, region‑specific variants) while still aligning structurally to the same group, sub‑group, and buying description.

Additional indicator values may be reserved in internal guidelines for special purposes (such as temporary codes or project‑specific applications), but 1 and 9 are the most widely referenced in public MESC documentation.

The final digit tells the whole story about an item’s standardization status:

Indicator | Meaning | Usage | Example |

1 | Central/Standard | Official catalogue item; use globally | 68.68.61.301.1 |

9 | Local/Regional | Same spec + local adaptation | 68.68.61.301.9 |

Practical Impact:

68.68.61.301.1 = Global green telecom cable (central standard)

68.68.61.301.9 = Same cable + local red color coding

Verdantis Approach to MESC Code Implementation

Verdantis applies its AI-powered MDM methodology to MESC exactly like it does for UNSPSC, automating classification, duplicate detection, and golden record creation while preserving MESC’s engineering precision.

Verdantis MESC Workflow:

Step | MESC Action | Outcome |

1. Data Extraction | Pulls legacy material masters | Raw MESC candidates + free-text |

2. AI Classification | Maps descriptions to MESC hierarchy | 95%+ auto-assigned Main/Sub/Sub groups |

3. Attribute Enrichment | Adds MESC-required specs (material, rating, ends) | Engineering-grade completeness |

4. L1/L2 Duplicate Detection | Finds MESC-equivalent items | “SS Pump 10HP” + “End Suction SS” → 40.15.15.003.1 |

5. Golden Records | Creates single MESC authority record | One 74.16.01.015.1 across 10 plants |

6. Continuous Governance | Monitors new data vs MESC standards | 98% compliance rate maintained |

How Verdantis AI Handles MESC Complexity:

- Understands engineering free-text (“SS ball valve 150# RF”)

- Learns from sparse MESC data

- Maps OEM spares to proper MESC classes

- Central (.1) vs Local (.9) logic automation

Proven Results (from Verdantis case studies adapted to MESC):

95% MESC classification accuracy

28% duplicate reduction (15 valve variants → 3 MESC codes)

$2.3M procurement savings via consolidated MESC spend

50% faster RFQ (MESC code = complete spec)

Example:

Before (10 plant descriptions):

- Plant A: “2 inch SS ball valve”

- Plant B: “74.16.01.015”

- Plant C: “SS 2\” 150psi flanged”

- Plant D: “Ball valve 316SS 50mm”

Verdantis Processing:

↓ AI Classification + Attribute Matching ↓

All → MESC: 74.16.01.015.1

Body: ASTM A182 F316

Ends: 150# RF ASME B16.5

SPE: 77/300

After: One Golden Record across enterprise.

Integration with Other Taxonomies

Verdantis maps MESC to UNSPSC/eCl@ss for external use:

Internal: 74.16.01.015.1 (MESC)

External: 40141616 (UNSPSC Ball Valves) 37070401 (eCl@ss Ball Valves)

Bottom Line: Verdantis turns MESC from manual effort to automated powerhouse: 95% classification, 28% deduplication, engineering precision maintained.

MESC vs. Other Classification Systems

While MESC is the industry standard in oil, gas, and heavy processing, organizations often encounter alternative data taxonomies:

Comparison: MESC vs. UNSPSC vs. eCl@ss

Dimension | MESC | UNSPSC | eCl@ss |

Origin & Governance | Shell (1932); proprietary; licensed | United Nations (1998); open standard | European consortium; open standard |

Code Format | 10 digits (XX.XX.XX.XXX.X) | 8 digits (XXXXXXXX) | 11–13 digits (varies by version) |

Coverage | ~80 main groups; 110,000+ items | 22,000+ codes; broad coverage | 13,000+ classes; strong in manufacturing |

Primary Use Cases | Oil, gas, chemical, power, heavy manufacturing | Cross-sector procurement; government; e-commerce | Manufacturing; automotive; electronics |

Language Support | English-based; regional adaptation | 22+ languages; global alignment | English + European languages |

International Standards Integration | API, ISO, ASTM, IEC cross-references | ISO, standards alignment | ISO 13584 (PLIB) foundation |

Supplier Ecosystem | Strong in O&G and heavy industries | Broad e-commerce and B2B platform adoption | Automotive and manufacturing suppliers |

Learning Curve | Moderate; requires industry expertise | Moderate; broad applicability | Steep; technical complexity |

Cost Model | Licensing fee; proprietary | Free/low-cost; open source | Licensing; variable pricing |

Strategic Selection Criteria

Scenario | Recommended System | Rationale |

Oil & Gas, Refining, Petrochemicals | MESC | Proven, industry-standard; deep integration with O&G operations; strong supplier alignment |

Manufacturing, Heavy Equipment, EPC Projects | UNSPSC or MESC | UNSPSC for broader supply chain; MESC for specialized equipment |

Automotive, Electronics, Precision Manufacturing | eCl@ss | Strong automotive/electronics ecosystem; detailed technical specifications |

Government Procurement, Multi-sector Procurement | Internationally recognized; government procurement mandates | |

Hybrid Approach | MESC + UNSPSC Bridge Mapping | Many large organizations maintain both; use MESC internally, UNSPSC for supplier/customer interfaces |

Key Insight: The choice is not binary. Leading organizations often implement MESC as their primary internal standard while maintaining mappings to UNSPSC and eCl@ss for supplier and customer alignment.

Creating the MESC Number for an Item (Non‑Spare Parts)

For non‑spare‑part materials (standard project or stock items), the creation of a new MESC number follows a controlled process:

Classify the material

Determine the correct main group, sub‑group, and sub‑sub‑group based on function, construction, and application.

Use the coding schedule and catalogue index to find the closest existing class.

Check for an existing standard item

Search within the chosen sub‑sub‑group for an item whose buying description already matches the required specification.

If found, adopt that code; duplication is avoided.

Define the specification

If no exact match exists, define a complete formatted specification (dimensions, material, rating, standards, tolerances, coatings, etc.).

Ensure compatibility with relevant international and company standards.

Assign the buying‑description digits

Allocate the next free 3‑digit number in that sub‑sub‑group for the new item.

Set the indicator

Use 1 for centrally approved items that will be incorporated into the official catalogue.

Use 9 if the item is local, temporary, or not yet suitable for central standardization.

Requests for new central codes are typically routed through a central standards organization or MESC coordination team, which reviews technical content before activation.

Real Example – Adding a new 2″ stainless steel ball valve:

Step | Action | Result |

1 | Classify valve | 74.16.01 (SS Ball Valves 150psi) |

2 | Search catalogue | No exact 2″ match exists |

3 | Create spec | Full formatted spec (material, ends, rating) |

4 | Assign number | Next available: .015 |

5 | Set indicator | 74.16.01.015.1 (central code) |

MESC Coding of Catalogue Items

Catalogue items are those already documented in the official MESC catalogue with a standard specification and often a drawing or data sheet.

Each catalogue line is assigned a unique MESC code, and the buying description segment directly references the standardized type, size, and execution defined in the catalogue.

Items are normally centrally coded (indicator 1) and may carry cross‑references to international standards (e.g., ISO, API, DIN) and recommended material grades.

Users are encouraged to first select from catalogue items instead of creating new local variants, to maximize standardization and leverage existing technical approvals.

Where catalogue ranges are wide (for example, valves or fittings), series of sequential MESC numbers cover variations in size, pressure rating, material, or end connection, all linked back to the same type drawing or specification sheet.

Catalogue items = Pre-approved, ready-to-order standards with complete specifications already defined.

Structure:

Catalogue Line → MESC Code → Formatted Specification → Drawing/Data Sheet

Example Range – Carbon steel gate valves:

74.10.00.001.1 → 2″ 150psi rising stem

74.10.00.002.1 → 3″ 150psi rising stem

74.10.00.003.1 → 4″ 150psi rising stem

Benefits:

Buyers order by code only (no specs attached)

Engineering pre-approved

Global supplier interoperability

Maintenance teams know exact replacements

Generic Items

Generic items are materials that are not fully specified to one precise design but are defined by broad, commonly accepted characteristics (for example, “general purpose bolts,” “miscellaneous fasteners,” or “not otherwise specified” versions within a class).

In the coding schedule, such items are often grouped under a generic sub‑sub‑group or marked with “NOS” (not otherwise specified) in their description.

Generic codes are used when the exact make, model, or minor dimensional variations are not critical to function, allowing more flexibility in sourcing.

Excessive use of generic items is discouraged for critical equipment, because it can reduce traceability and performance consistency; the guidelines recommend moving high‑volume or safety‑critical generics into fully specified catalogue items over time.

Generic = “Close enough” specifications for non-critical, interchangeable items.

Type | Example | When to Use | MESC Example |

NOS | “Bolts M12 general purpose” | Low criticality | 56.12.99.001.1 |

Broad Class | “MS mild steel plate 10mm” | Standard stock | 51.23.10.050.1 |

Family Generic | “Pipe insulation 50mm” | Utility items | 76.25.50.001.1 |

Caution: Limit generics to <10% of critical inventory. High-volume generics should graduate to full catalogue specifications.

MESC Coding in E‑SPIR 2000

E‑SPIR (Electronic Spare Parts Interchange Recommendation) 2000 is an electronic format used between equipment manufacturers and operating companies to exchange recommended spare parts data.

In E‑SPIR 2000, each manufacturer spare part line can be associated with a MESC code, in addition to the OEM part number.

This linkage allows operators to integrate supplier‑proposed spares directly into their own material masters under MESC, which supports evaluation, consolidation of equivalent parts, and stock planning across multiple assets and vendors.

The guidelines recommend that, where a suitable MESC class already exists for a spare, the part should be coded accordingly; if not, it may be handled temporarily as an unformatted item (spare‑part method) until a proper class and formatted description are created.

E-SPIR 2000 = Electronic standard for OEMs to submit recommended spares lists to operators.

Dual Identification:

OEM Part No: ABC123456

MESC Code: 27.15.23.045.9

Description: Pump impeller type X

Benefits:

Operators receive spares data already MESC-classified

Enables duplicate detection across OEMs

Supports automatic material master population

Facilitates “best cost” spare selection

Formatted Item Specifications

Formatted item specifications are structured, template-based descriptions used for standard materials listed in the MESC catalogue.

They typically include:

Designation and MESC code

Dimensional data (sizes, face-to-face lengths, connection types)

Material composition (body, trim, seals, coatings)

Pressure and temperature ratings, along with service limits

Applicable standards and testing requirements

The key advantage of formatted specifications is that they provide a complete engineering definition of an item. This allows buyers to place orders using only the MESC code, without needing to attach separate technical documents each time.

These specifications are preferred for frequently used or critical materials because they simplify purchasing, ensure consistency, and reduce the risk of errors.

Complete engineering definitions for catalogue/standard items:

- MESC: 74.16.01.015.1

- Item: 2″ SS Ball Valve 150psi

- Body: ASTM A351 CF8M (316 SS)

- Trim: 316 SS Ball + Seats

- Ends: 150# RF Flanged

- Rating: -29°C to 425°C, 150psi

- Test: API 598

- Drawing: MESC-DWG-741601015

Use When: Standard/repeat items needing complete specs.

Unformatted Item Specifications

Unformatted item specifications are mainly used for spare parts and OEM-specific components when creating a full standardized template isn’t practical or required.

Typical details include:

Manufacturer name

Manufacturer’s part number

Short description

Equipment reference or tag number

In these cases, the MESC code usually follows a spare-part style structure. The buying description range is assigned based on the manufacturer or equipment type, while the unique identification details remain tied to the OEM part number instead of a detailed formatted specification.

Even though unformatted specifications don’t include full technical data, they still benefit from MESC in terms of grouping, valuation, and inventory management. However, the exact engineering definition continues to be documented by the OEM.

OEM-specific spares identified by manufacturer data:

MESC: 27.15.99.123.9

Manufacturer: Flowserve

Part No: 21CA789

Description: Shaft, Pump Type A

Equipment Tag: P-102A

Use When: Unique spare parts, manufacturer-specific components.

Quick Reference: Formatted vs Unformatted

Characteristic | Formatted | Unformatted |

Primary Use | Catalogue standards | OEM spares |

Content | Complete engineering spec | Manufacturer + part no |

Examples | Valves, fittings, pipes | Impellers, seals, gears |

MESC Indicator | Usually 1 (central) | Usually 9 (local) |

Procurement | Order by MESC code only | Requires OEM reference |

Supplier | Multiple competitive | Often single source |

Golden Rule: Always prefer formatted specifications. Use unformatted only when engineering standardization isn’t practical.

Advantages of MESC Standardization

MESC transforms procurement chaos into precision. Here’s how:

Benefit | Impact | Example |

Procurement Speed | 50%+ faster RFQs | Single code replaces 5-page specs |

Quality Guaranteed | ISO/API/ASTM cross-referenced | No more “wrong alloy” disasters |

Supply Chain Freedom | Multi-supplier competition | Same code works across 10 vendors |

Inventory Savings | 15-25% reduction | 15 valve variants → 3 standards |

Maintenance Predictability | Faster repairs | Technicians know exact spares |

Digital Evolution: From 2-meter paper catalogues to cloud-based CMT (Catalogue Management Tool) with real-time specs and ERP integration.

Bottom Line: MESC = one code, one spec, worldwide reliability across procurement, quality, inventory, and maintenance.

Conclusion

The MESC is a mature and highly effective system for standardization and classification that has evolved over nearly a century. Its ten-digit hierarchical coding, three-part structure, and flexibility to include both global standards and local variations reflect a deep understanding of how complex industrial operations function.

For procurement teams, asset managers, engineers, and supply chain leaders in industries like petroleum and chemical processing, MESC is far more than just a data management tool- it’s a universal language that enables consistent supply chain coordination, quality control, and operational reliability across the world.

As organizations continue to digitize their materials management systems, MESC codes act as semantic bridges-turning human-readable descriptions into machine-recognizable identifiers that seamlessly connect procurement platforms, inventory systems, maintenance tools, and enterprise resource planning (ERP) solutions.